AUTHOR: Fazley Rabby Patwary

MENTOR: Md. Motiur Rahman

SUPERVISOR: Dr. Debasish Sarker

PROGRAM: Bachelor of Science in Mechanical Engineering

DEPARTMENT: Department of Mechanical Engineering

INSTITUTION: International University of Business Agriculture and Technology

SUBMISSION: Spring, 2025

KEY WORDS: UAV propeller, Blade optimization, Computational fluid dunamics (CFD), Genetic algorithm (GA), Aeroacoustic Noise Reduction

ABSTRACT: Unmanned Aerial Vehicles (UAVs) are increasingly used in applications such as surveillance, delivery, and agricultural monitoring, where propeller-generated noise and limited energy efficiency remain critical challenges. This study presents an integrated optimization framework for UAV propeller design aimed at reducing aerodynamic noise while improving performance and energy efficiency. A Genetic Algorithm (GA) is employed to optimize key geometric parameters, particularly chord length and blade-tip features, using Blade Element Momentum Theory (BEMT) for rapid performance evaluation. High-fidelity Computational Fluid Dynamics (CFD) simulations in ANSYS Fluent are used to analyze flow structures, vortex formation, and aerodynamic behavior, while the Ffowcs-Williams/Hawkings (FW-H) acoustic model predicts noise characteristics. To validate the numerical results, baseline and optimized propellers were fabricated using 3D printing and experimentally tested for thrust, torque, power consumption, and acoustic emissions. Results indicate a 4–5% improvement in thrust-to-torque ratio for the optimized design, enabling equivalent thrust generation with reduced power usage. Additionally, tonal noise at the Blade Passing Frequency (BPF) is reduced by approximately 1.5–2 dB. These findings demonstrate that targeted geometric modifications can significantly enhance UAV propeller efficiency and noise performance, contributing to extended flight times and improved suitability for noise-sensitive environments.

CAD Model

Baseline 8045 Propeller

Modified GA Propeller

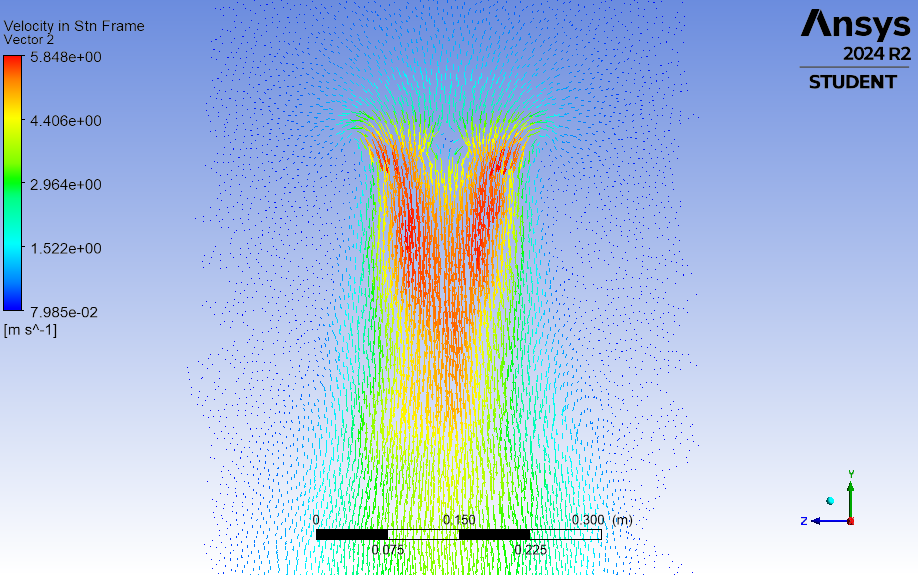

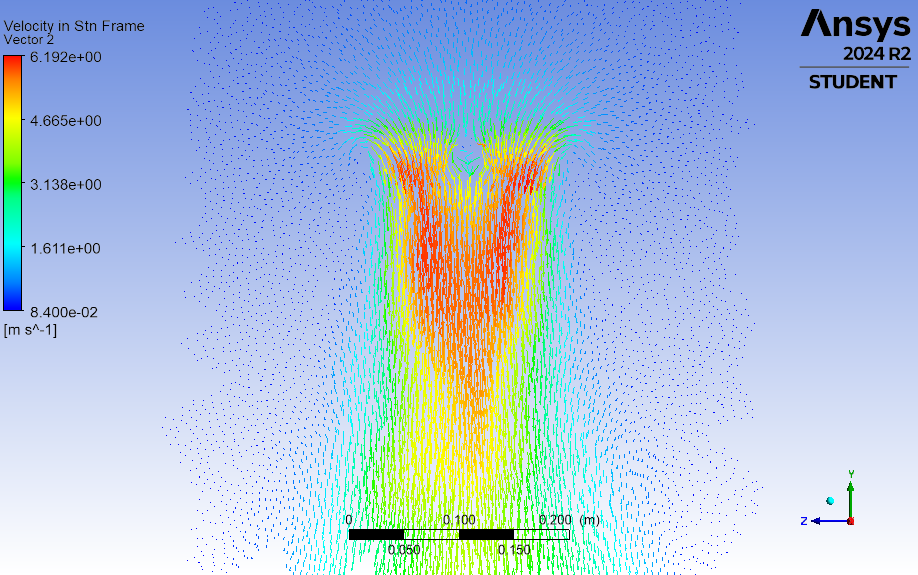

Flow Field Analysis Using CFD

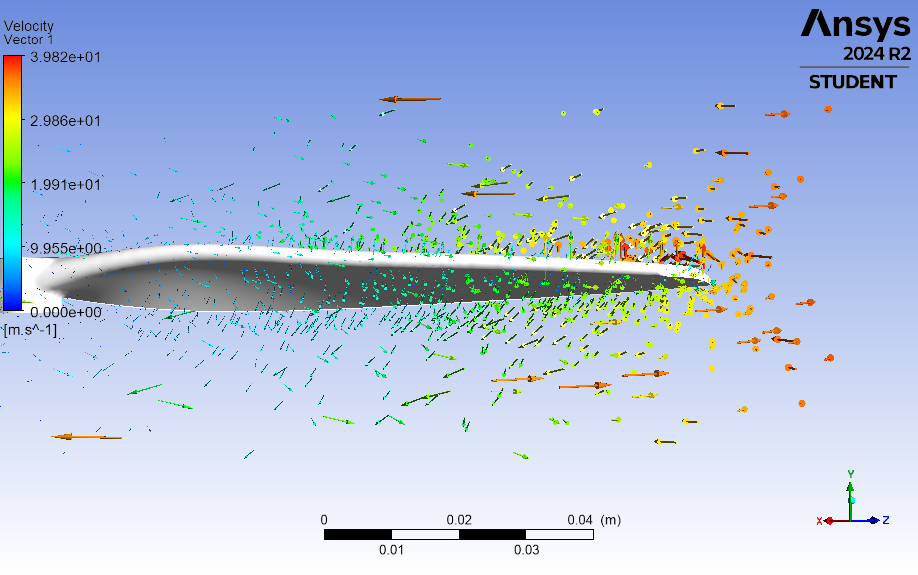

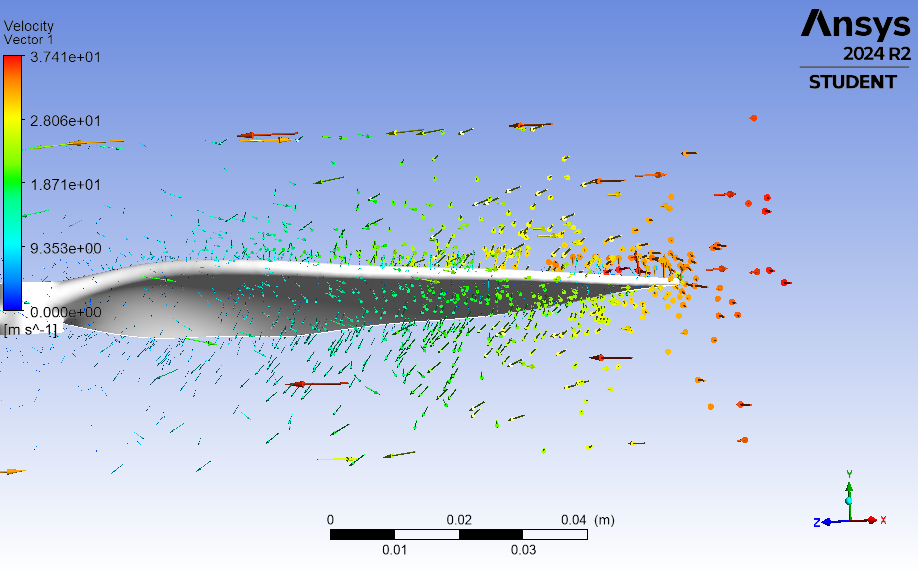

Tip Vortices Study Using CFD

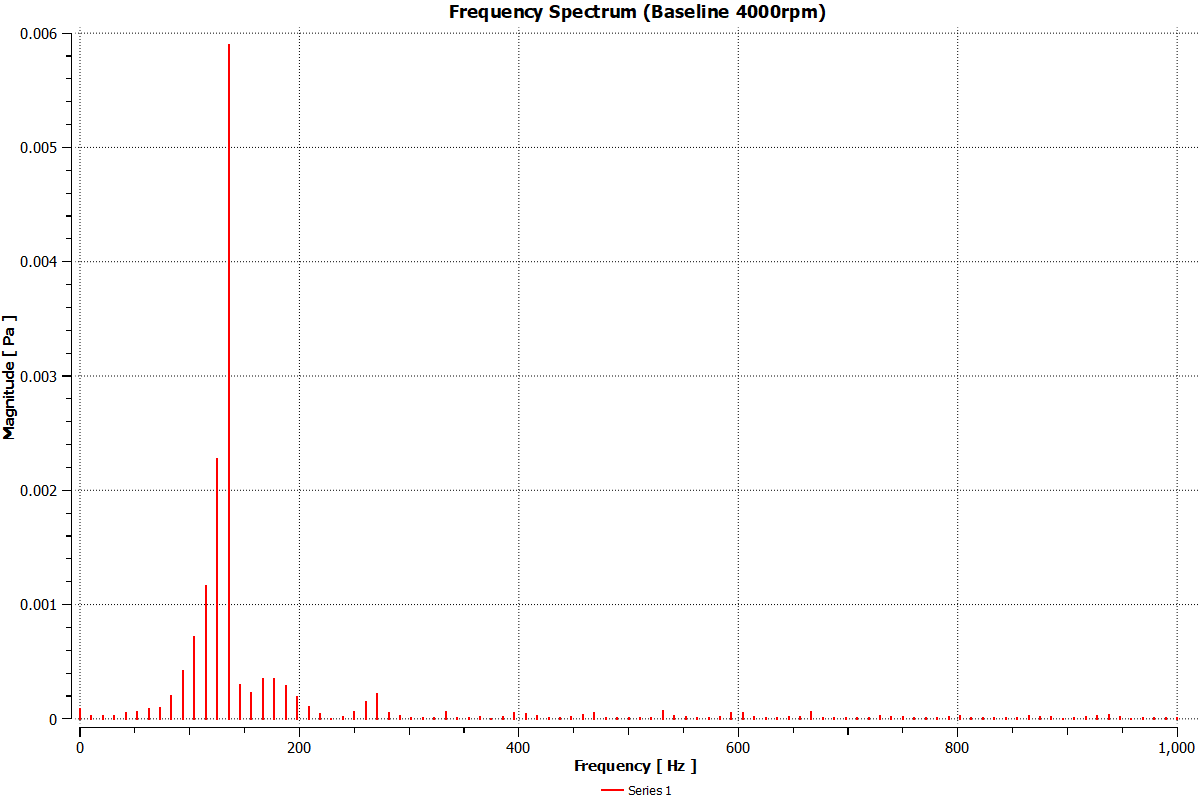

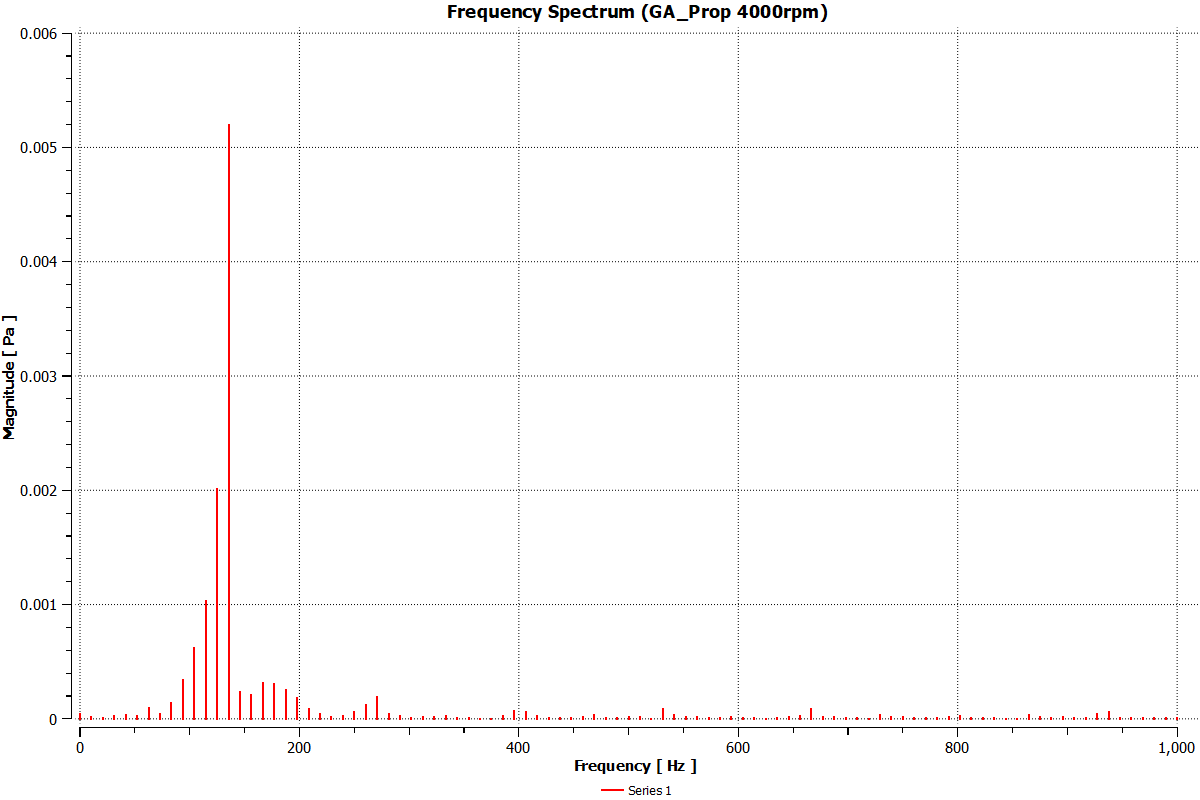

Aeroacoustic Noise Comperison Using FW-H Acoustic Model

Experimental Setup

Conclusion

This study focused on optimizing UAV propeller design to improve aerodynamic efficiency using a combination of Genetic Algorithm (GA)-based optimization, Computational Fluid Dynamics (CFD) simulations, and experimental validation. The research successfully demonstrated that targeted modifications to propeller geometry, particularly at the tip, can achieve significant

improvements in aerodynamic performance. Key findings include:

The GA-optimized propeller achieved a 4.02% to 4.70% improvement in aerodynamic efficiency compared to the baseline design, primarily due to reduced torque requirements. This translates to lower power consumption and extended flight endurance for UAVs.

The tip modification also had the secondary benefit of reducing tonal noise at the Blade Passing Frequency (BPF), with lower Sound Pressure Levels (SPL) observed across all tested RPMs (3000, 4000, and 5000 RPM). This was achieved by weakening the tip vortex strength, a major source of tonal noise.

The experimental results closely matched the CFD simulation predictions, validating the accuracy of the computational models and the effectiveness of the GA-based optimization approach. This consistency between simulation and experimentation underscores the reliability of the proposed design methodology.

The optimized propeller design offers a balanced solution for UAV applications, combining improved aerodynamic efficiency with secondary noise reduction benefits. This makes it particularly suitable for missions where energy efficiency is critical, such as long-endurance surveillance, delivery operations, and military applications.